PFM 9.1 DRO

THE CLASSIC WORKHORSE

The PFM 9.1 DRO is based on the original lathe that was imported from Sweden in 1989. It's our smallest and simplest lathe: a stripped down version that handles like a sports car and will do everything you ask of it. For basic functionality, this is your choice. Now with 1.0 hp motor, disc-lock trolley, and DRO computer that measures lathe use, performance, and ROI. This machine can handle most passenger vehicles, SUV's, and pickup trucks. LED compensation indication lights alert the technician when machine is ready to cut. Bolt-down dovetail cutting head, 5 piece adapter package, and basic accessory kit all come standard. Set up and training included in the US and Canada.

Key Features

- 1.0 HP motor has all the power you'll need and the convenience of a 110v power supply.

- PFM computerized compensation now with enhanced programming and live digital read-out.

- Disc-lock trolley makes changing sides simple and fast with sealed bearings and a positive locking mechanism.

- Bolt down cutting head with 8 hole slide plate for wide adjustment range.

- Aluminum body provides natural vibration dampening and is virtually indestructible.

What's Included

- Pro-Cut 9.1 on-car brake lathe

- DRO computer box (G2X/GYR upgrades N/A)

- Speed-lock cutting head

- Disk-lock Trolley

- 5 adapter package (7 adapter package $700 extra)

- All accessories including silencer and cutting bits

- On-site installation and training

I'D LIKE TO REQUEST...

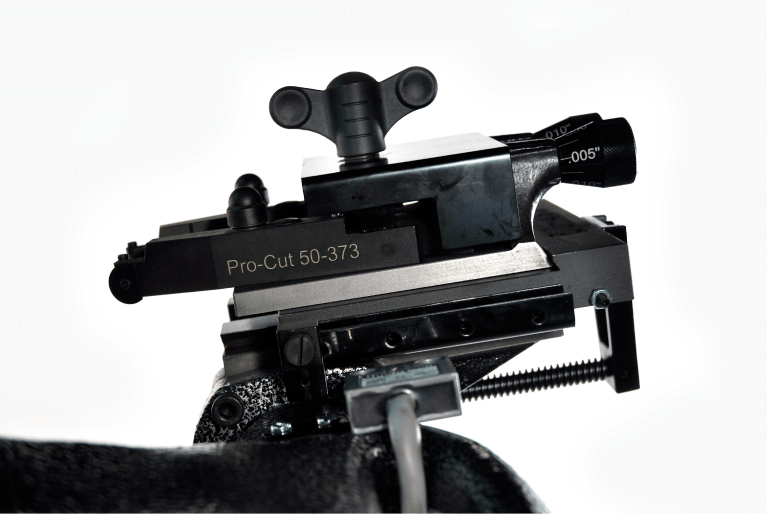

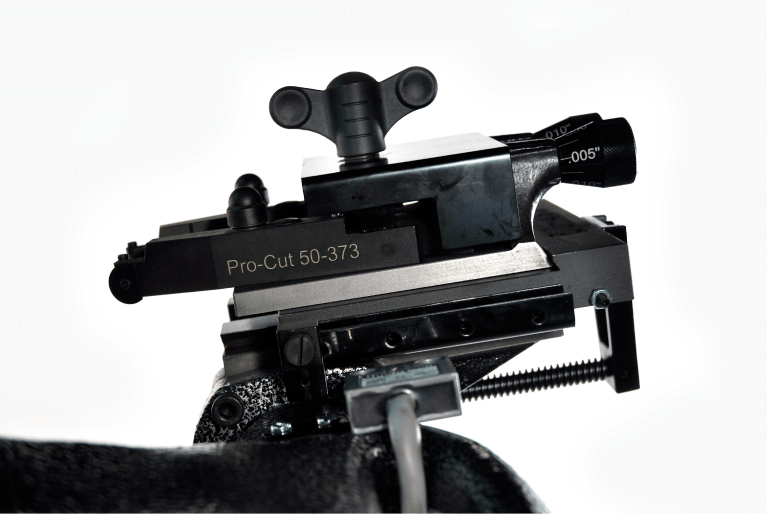

50-373

50-373 Detail of 9.1 DRO

Detail of 9.1 DRO 50-373

50-373 Detail of 9.1 DRO

Detail of 9.1 DRO